With the rapid advancement of technology, precision optical components have become indispensable core elements of modern electronic devices. From digital cameras to smart home appliances, from vehicle-mounted systems to aerial drones, the performance and reliability of these devices largely depend on the precision manufacturing of optical components. Dayan Intelligent Manufacturing’s laser soldering technology, with its outstanding product advantages and brand strength, provides innovative solutions for the precision soldering of optical components.

1.The Challenges of Precision Soldering for Optical Components

The manufacturing of optical components demands soldering processes that achieve high precision and miniaturization to accommodate their compact structural designs. Although traditional brazing techniques are well-established, they still present limitations in the realm of precision soldering. Laser soldering technology, as an extension of brazing techniques, has emerged as an ideal choice for precision soldering due to its advantages such as high energy density, rapid soldering, and minimal heat-affected zones.

2.The advantages of Dayan’s laser soldering technology are as follows:

Dayan’s laser soldering technology utilizes high-quality semiconductor lasers, offering the following notable advantages:

- High Soldering Precision: Semiconductor lasers provide excellent beam quality and a small focused spot, enabling precise soldering at minute intervals.

- Minimal Thermal Impact: The laser soldering process has a small heat-affected zone, preventing damage to sensitive components.

- Ease of Operation: A modular control system automates the feeding of solder wire and the emission of laser light for soldering.

- Environmentally Friendly and Safe: The non-contact soldering process eliminates the need for flux, ensuring a clean and eco-friendly operation.

- Constant Temperature Control: PID algorithms ensure stable temperature throughout the soldering process, enhancing soldering quality.

3.The application of laser soldering technology in optical components is as follows:

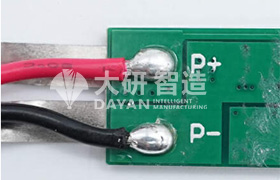

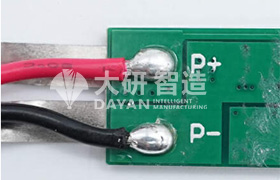

- Laser Wire Soldering: Suitable for soldering electronic components such as PCB boards and optical components. The materials are clamped once, and the soldering is completed automatically.

- Laser Solder Paste Soldering: Suitable for soldering precision devices like optical communication modules and optical components. The connection is achieved by pre-filling solder and heating through laser irradiation.

- Laser Solder Ball Jetting: Suitable for fine soldering in the 3C industry, such as hard drive heads and mobile phone camera modules. It uses non-contact heating, ensuring no thermal impact on the overall package.

4.The practical benefits of Dayan Intelligent Manufacturing’s laser soldering technology

By adopting Dayan’s laser soldering technology, optical component manufacturers can significantly enhance product quality and production efficiency while reducing manufacturing costs. The constant temperature control and online real-time power monitoring features ensure the stability and consistency of the soldering process, minimizing the risk of soldering defects.